Innovation through Design & Development

Controlled Atmosphere Multi Product Storage Facility Designed and Developed by Kala Freeze n Cold Technologies – a division of Kala Biotech Pvt Ltd provides state of Art Cold Chain Facility suitable for Logistic/ Backend support for E-commers company, Pharma C&F, Food Product, Dairy C&F. Kala facilitated Cold Chain Facility with all allied equipment and very much suited for Fresh Vegetables & Fruits, Dry Fruits, Spices, Grains & Cereals, Sowing Seeds, Dairy products, Pharma Products, Chemicals etc.

Kala Biotech has successfully developed a Controlled Atmosphere Multi Storage Structure Facility in Technical collaboration with ICAR-DOGR with losses of Less than 15% while maintaining the shelf life of Agri Produce.

The Facility has fully operational Washing, Sorting, Grading, Packing, Pre-cooling, Ripening, Short-term, Long-term Cold Storages.

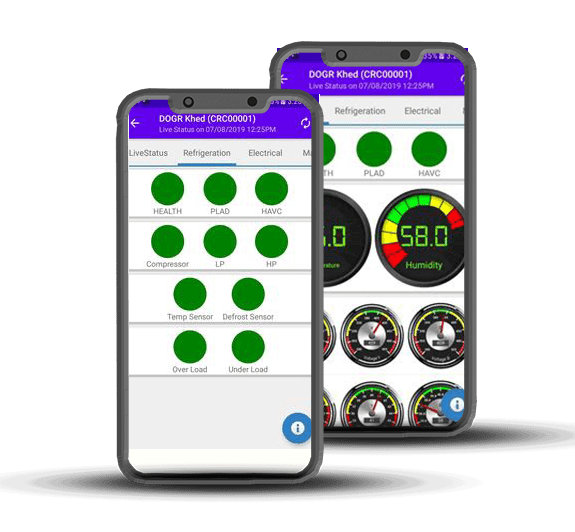

Kala has got its own Kkloud™ - A IOT based system with Innovative features like Remote monitoring, Controlling, and Data Analytic system, System health updates on refrigeration and electrical parameters, Live reports on available stocks, and market rates.

Controlled Atmosphere Multi Product Storage Facility will be a great help for Farmers, FPC’s with following points:

- Price Stabilization at the market place Strengthening the Agri Produce value chain.

- Contribution to reduce the carbon footprint with minimum storage losses.

- This innovative Storage Structure provides End to End Solution including Integrated Pack House, CA Facility, Pre-cooling, Ripening, Grading & Sorting system and Conveyorised Material Handling System

- Relief to farmers from distress selling during the glut period.

- Quality produce with fewer storage losses.

- Increased availability of Agri Produce for domestic consumption and export.

- Can be used to store other horticulture products and crops which require temperatures between 0-40⁰c & RH between 50-95%.

- Aids in doubling a farmer's income.

- Ripening Chambers can be utilized as additional facilities in the same premise to generate additional income.

- The Facility is suitable for Pharmaceutical Companies to preserve their Stocks at a very economical rate.

Advantages of Controlled Storage Structure

- Structure can be constructed from 50 to 100 MT capacity for low cost farm level and from 800 to 2000 MT capacity for commercial scale with all integrated automatic material handling, sorting and grading facility

- All the models have Kkloud™ facility for remote monitoring and controlling of all the parameters

- All the structures have options for artificial curing also to reduce the storage losses specially during kharif season

- Through evaluation gave encouraging results with minimum losses less than 15% as compared to 40-60% in naturally ventilated structures

- The post storage behavior of onion was also found encouraging with no sprouting up to two months after taking out from storage structure where as in cold storage (0-5˚C) the sprouting is the major bottle neck (100% sprouting within a week)