Onion Storage Structures

Kala Biotech has successfully developed a Controlled Atmosphere Onion Storage Structure in Technical collaboration with ICAR-DOGR with losses of Less than 15% while maintaining the shelf life for 8 months. A prime requirement of any Storage Facility is grading, sorting, loading, unloading, and complete material handling system, which is aptly addressed here.

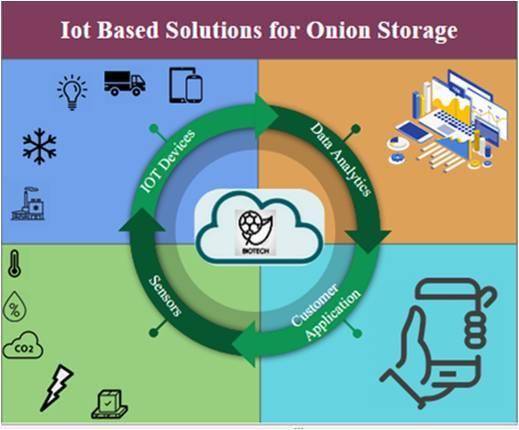

Kala has got its own Kkloud™ – A IOT based system with Innovative features like Remote monitoring, Controlling, and Data Analytic system, System health updates on refrigeration and electrical parameters, Live reports on available stocks, and market rates.

Controlled Atmosphere Onion Storage will be a great help for Farmers, FPC’s with following points:

- Despite the strong growth rate in Agree production, extreme price volatility is creating havoc in the country.

- Price Stabilization at the market place Strengthening the onion value chain.

- Contribution to reduce the carbon footprint with minimum storage losses.

- This innovative Storage Structure provides End to End Solution including Integrated Pack House, CA Facility, Pre-cooling, Ripening, Grading & Sorting system and Conveyorised Material Handling System

- Relief to farmers from distress selling during the glut period.

- Quality produce with fewer storage losses.

- Increased availability of onions for domestic consumption and export.

- Can be used to store other horticulture products and crops which require temperatures between 16 to 40⁰c.

- Aids in doubling a farmer's income.

- Ripening Chambers can be Constructed and utilized as additional facilities in the same premise.

Benifits of The Controlled Atmosphere Onion Storage Facility

- Onion Storage with temperature from RH 50-95%

- Drying Chamber with temperature above 40°C plus.

- Ripening Chamber as additional facility

- Possibility for artificial curing and storage for reducing sprouting loss during Kharif season.

- Increased availability of onions for domestic consumption and export.

Primary Processing, Grading & Sorting, Storage and Pack House Facility

In order to provide the complete solution for easy storage, a system involved in sorting and grading units, loading & unloading conveyor system are

also designed along with a pack house including bag filling facility & weighing scale for packing and marketing of onion at the end of the storage